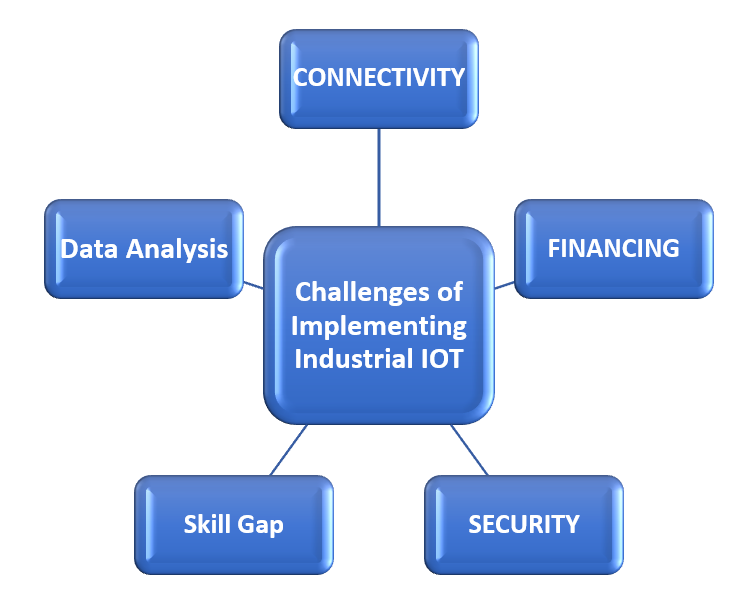

Top 5 Challenges of Implementing Industrial IOT

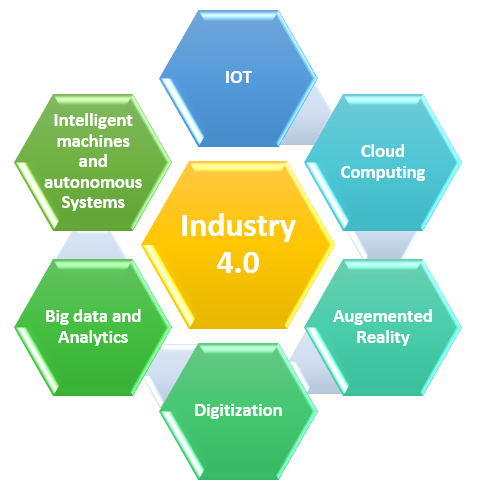

IoT solutions have not only conquered our homes in recent years, they are also being used more and more frequently in industry. IoT deployment is diversifying from consumer-based applications to mission-critical applications in the industrial sector and playing a critical role in the next phase of factory automation, which has been called Industry 4.0. The industrial IoT (IIOT) offers companies the full digitization of production processes, cooperating the digital and physical worlds within the factory. The most common scenarios for IIOT include predictive maintenance, intelligent measurement technology, asset management, and fleet management.

During this global financial crisis of Covid19, more and more industrial companies are turning to the IIOT to remotely monitor their systems and prevent unplanned downtime. A survey by Microsoft found that 85% of companies have at least one IoT project in the works, and a recent forecast by Million Insights predicted that the Industrial Internet of Things (IIoT) could reach a whopping $992 billion in global spending by 2025. Even though IIOT is transforming the future of manufacturing, it does bring some serious challenges as companies start to accelerate their digital transformation. Here below are listed top 5 challenges that companies have to face in their implementing phase of IIOT.

High-Investment and Ownership Cost

The cost of industrial IoT products and their deployment are obviously very high. Sure, one of the main promises of industrial ITO is to improve manufacturing efficiencies and reduce costs through better asset management, access to business intelligence, and productivity gains. However, not only development but support should be considered along with high skill resources who are expert in IoT. So, the overall cost of industrial IoT application implementation is very high. And it’s hard for organizations to justify the cost when they’re not entirely sure what kind of ROI to expect at first.

Connectivity

One of the main requirements for adopting the IIOT is having reliable data networks with sufficient capacity. IIoT connectivity should be a forethought before deployment, not an after thought. Studies shows that in 85% of worldwide factories, machines are not connected and are unable to collect / provide data and transmit back to the centre for analysis. One of the main reasons is because legacy devices have a lifespan of 30-60 years and do not support data-driven tools and offer few connectivity options. On the other hand, the number of connected devices is growing at a much higher rate than the network coverage, which creates monitoring and tracking problems. Also, because the Internet is still not available everywhere at the same speed, connectivity issue is the one of the biggest challenges in IIOT deployment. Thus, having scalable IoT network to connect devices and servers is critical for a large scale industrial IoT app.

Cybersecurity

Securing industrial IoT devices is a challenge in itself for a number of reasons. With this expansion of the industrial IOT, the attack surface for companies also increases. In case of any successful attack on industrial IOT, not only sensitive data is realised, but it can also cause massive physical damage to machines and bring the entire production of manufacturing companies to a standstill. Thus, security challenges for IIoT technologies are the biggest concern as the breaches affect both individuals and organizations vulnerable to financial and operational damage.

When it comes to protection, most cybersecurity protection tools only focus on network and cloud but misses the endpoint and OTA vulnerabilities. “According to IDC, 70% of security breaches originate from endpoints. While organizations may not be able to eliminate all industrial IoT attacks from occurring, OTA vulnerabilities and potential point of entries into endpoint devices should be identified, and devices should be tested using a regularly-updated database of known threats/attacks to monitor device response and detect anomalies”. The ultimate goal for companies and their industrial processes is not only need to adapt to this rapid change but also avoid being target for hacking groups.

Data Analysis

A common method for implementing IoT solutions in industrial environments is to expand manufacturing facilities with tools for data acquisition, analysis and visualization. These include sensors, IoT gateways, human-machine interfaces and cloud-based analysis tools that transform raw data from devices into usable insights.

The analysis of data is important to make this voluminous amount of data being produced in every minute via the rapidly growing number of sensors, embedded systems and connected devices as well as the increasing horizontal and vertical networking of value chains, useful. In multiple organizations, this valuable data isn’t being used in a structured and sufficient manner. It is important for business organizations to hire a data scientist having skills that are varied as the job of a data scientist is multidisciplinary and the critical business decisions should be taken effectively.

Skill Gap

Industrial IOT project owners realise that one of the most challenging issues with industrial IoT is the skills gap and how to address this issue. Industry is undergoing a rapid change right now and companies have been raising worries of a lack of technical staff. Absence of qualified staff is impacting many areas within the company. According to Microsoft’s 2019 IoT Signals report, 29% of organizations reported that a lack of resources was one of the top reasons for holding off on IoT adoption. For many manufacturers, finding qualified staff to design, deploy and maintain modern industrial networks and the urgent need to update and transform business operations is huge challenge.

Sources:

- Industry 4.0 – Opportunities and Challenges of the IIOT

- Industrial IoT Delivers Smarter, More Connected Factories

- Industry 4.0: the fourth industrial revolution – guide to Industry 4.0

- Exploring top five challenges through the 5Cs of IoT